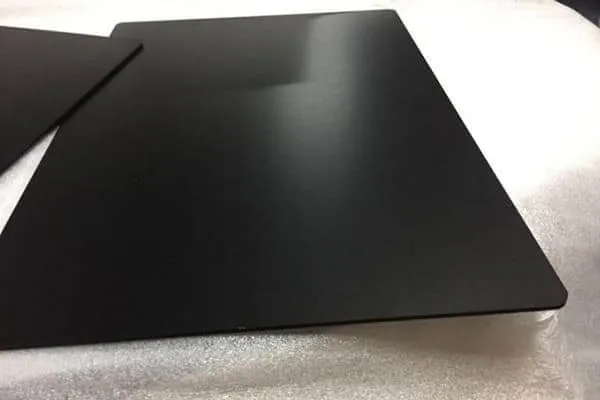

Aluminium systems used in demanding applications rely heavily on surface finishing to achieve durability, stability, and long-term performance. Among advanced treatments, black anodised aluminium stands out for its ability to enhance resistance against corrosion, wear, and environmental exposure while maintaining a refined appearance. These finishing techniques play a vital role in strengthening aluminium systems used across architectural, industrial, and infrastructure projects.

Precision Engineering Through Surface Preparation

Proper surface preparation removes contaminants, evens out microscopic imperfections, and creates a stable base that allows coatings or treatments to bond effectively.

- Mechanical Cleaning and Degreasing

Mechanical cleaning eliminates oils, dust, and residues accumulated during extrusion and handling. This process ensures that the aluminium surface remains uniform and receptive to further treatments. Without thorough degreasing, surface finishes may fail prematurely, leading to peeling or uneven texture under environmental pressure. - Surface Abrasion Control

Controlled abrasion smooths inconsistencies while preserving structural integrity. This balance allows the aluminium to retain strength while achieving a finish-ready texture. Precision abrasion also improves adhesion, ensuring long-term durability across applications exposed to vibration or load-bearing stress. - Chemical Etching for Uniformity

Chemical etching refines the surface at a microscopic level, removing oxides and irregularities. This step enhances consistency across aluminium profiles, especially in large-scale systems. Uniform etching supports predictable finishing results and reduces visual or performance variations. - Rinse and Neutralization Processes

Rinsing removes residual chemicals that could interfere with surface treatments. Neutralization stabilizes the aluminium, preventing unwanted reactions during subsequent finishing stages. These steps contribute significantly to long-term corrosion resistance and finish stability. - Inspection Before Treatment Application

Visual and technical inspections identify defects before finishing begins. Early detection allows corrections that prevent costly failures later. This quality-focused approach strengthens reliability in finished aluminium systems.

Anodizing Techniques for Structural Longevity

Within this category, black anodised aluminium is applied in systems requiring enhanced durability, dimensional stability, and controlled aesthetics.

- Electrochemical Oxide Layer Formation

The anodizing process creates a controlled oxide layer through electrochemical reactions. This layer becomes part of the aluminium itself rather than a surface coating. As a result, it resists peeling and delivers consistent performance under fluctuating temperatures. - Thickness Control for Performance Balance

Managing oxide layer thickness ensures durability without excessive material stress. A balanced layer enhances wear resistance while preserving flexibility and load-bearing capacity. Thickness consistency also improves predictability across large aluminium systems. - Color Stability and Light Absorption

Anodized finishes offer excellent color retention even in harsh climates. Light absorption properties reduce glare and support thermal efficiency in exposed installations. This stability supports long-term visual and functional reliability. - Improved Surface Hardness

Anodizing significantly increases surface hardness, protecting aluminium from scratches and friction-related damage. This hardness is essential for systems exposed to frequent handling or mechanical movement. - Environmental Resistance Enhancement

The anodized surface acts as a barrier against moisture, pollutants, and corrosive agents. This protection extends service life and reduces maintenance requirements in demanding environments.

Protective Coating Systems for Environmental Exposure

When applied to anodised aluminium sections, these coatings enhance resistance to chemical exposure, prolonged humidity, and extreme temperature variations while maintaining structural stability.

- High-Adhesion Coating Technologies

Modern coating systems are designed to bond strongly with prepared aluminium surfaces. High adhesion minimizes cracking and delamination over time. This reliability supports aluminium systems used in infrastructure and industrial settings. - Barrier Protection Against Corrosive Elements

Protective coatings form an external shield that blocks moisture and contaminants. This barrier prevents corrosion from penetrating the metal substrate. Effective barrier systems extend the lifespan of aluminium installations significantly. - Thermal Stability Under Temperature Variations

Advanced coatings maintain integrity despite thermal expansion and contraction. This stability prevents surface stress and cracking. It is especially critical for aluminium systems installed in regions with extreme temperature fluctuations. - Chemical Resistance for Industrial Applications

Coatings formulated for chemical resistance protect aluminium from acids, salts, and industrial pollutants. This resistance ensures consistent performance in manufacturing and processing environments. - Reduced Maintenance and Lifecycle Costs

Durable coatings minimize the need for frequent inspections or repairs. Lower maintenance demands translate into reduced operational costs and long-term efficiency.

Precision Finishing for Structural Consistency

Precision-controlled finishing ensures uniform performance across profiles, assemblies, and installations.

- Consistency Across Production Batches

Standardized finishing processes maintain uniformity between production runs. This consistency supports seamless integration during installation and assembly. Reliable finishes reduce compatibility issues in large-scale projects. - Improved Joint and Connection Stability

Finished surfaces enhance the fit and function of joints and connectors. Smooth, controlled surfaces reduce friction-related wear at connection points. This improvement supports long-term structural reliability. - Enhanced Load Distribution

Uniform surface finishes help distribute stress evenly across aluminium systems. Balanced stress distribution minimizes fatigue and deformation. This property is critical in structural and load-bearing applications. - Surface Smoothness for Functional Performance

Smooth finishes improve movement in sliding or adjustable components. Reduced resistance enhances operational efficiency and user experience. - Alignment with Engineering Specifications

Precision finishing ensures compliance with strict engineering tolerances. Accurate finishes support predictable performance and safety standards across industries.

Sustainability Through Advanced Finishing Processes

Aluminium systems benefit from finishes that extend lifespan while reducing resource consumption.

- Extended Product Lifecycle

Durable finishes reduce the frequency of replacement. Longer service life lowers material demand and waste generation. This efficiency aligns with sustainable construction and manufacturing goals. - Reduced Resource Consumption

Advanced finishing minimizes the need for repeated treatments or repairs. Lower resource usage contributes to energy and material conservation. - Environmentally Controlled Processes

Modern finishing systems incorporate controlled chemical usage and waste management. These practices reduce environmental impact while maintaining performance standards. - Recyclability Preservation

Finished aluminium retains recyclability at the end of its lifecycle. This characteristic supports circular economy practices without compromising durability. - Support for Green Building Standards

Durable aluminium systems with advanced finishes contribute to sustainable building certifications. These systems support long-term environmental performance objectives.

Conclusion

Advanced surface finishing techniques play a crucial role in ensuring aluminium systems deliver durability, consistency, and long-term performance in demanding applications. By combining precise preparation, controlled anodizing, protective coatings, and sustainability-focused processes, aluminium achieves reliability that extends well beyond basic structural requirements. The performance advantages of anodised aluminium sections demonstrate how thoughtful finishing directly influences lifecycle efficiency and environmental resilience.

This commitment to advanced finishing standards is reflected in manufacturers such as JM Aluminium, where surface treatment expertise aligns with precision extrusion and quality-driven production. Through controlled processes and a focus on long-term performance, the company supports aluminium systems engineered to perform reliably across diverse and challenging environments.